History of Millington Engines

Roy Millington started working on agricultural diesel units and building engines in 1971 on the family farm, near Bridgnorth in Shropshire.

Roy progressed to re-boring BMC A-series engines and then modifying Ford crossflow cylinder heads for Autograss cars.

In 1977 Roy designed and built the well known and originally controversial Class 8/9 BC02 Special, which has been said to have shaped Autograss into a more serious and professional sport. Roy raced the special, with its BDG engine, as did his wife Sheila – the latter achieving fastest lap of the day at the National finals (including men and women) which lead to her being banned from mens races. This would not happen today! Eventually Roy established a name and a reputation which lead to building and repairing rally engines for Ford Escorts and Opal Manta 400s. In turn, this created a client base running Ford BDA engines.

In 1988 Roy saw that the BDA was ageing in rallying, expensive to maintain and the parts were proving difficult to source – yet, they remained popular.

Back then it was becoming popular to strip the turbo from Cosworth YB's, opening up the ports and using them in N/A form. What they then had, was a readily available engine with no part supply problems.

Roy Millington's vision, went even further, the only problem was the YB's heavy Cast Iron block.

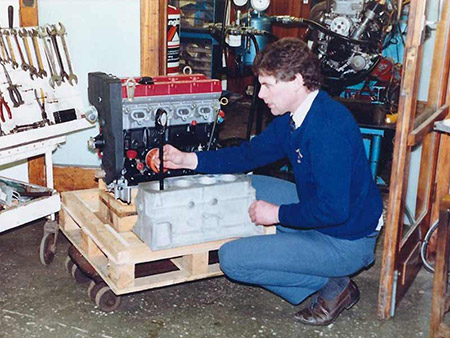

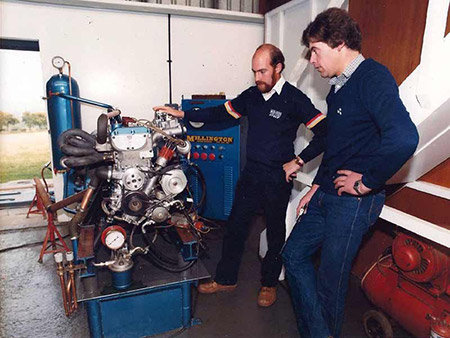

Roy could see the need for an all-alloy no-compromise race version of the YB, so initiated a light weight aluminium block project. Richard Jenvey (now well known in motorsport with Jenvey Dynamics) cast the first 30-40 blocks in 1989. Roy machined them and used modified production heads producing the first Millington Diamond Engines.

At the time Tim Duffee of Darrian Sports Cars was looking for a production based engine for his new T90 Sports car.

In 1990 Tim approached Roy about supplying an engine, as it happened the first Millington prototype engine (2.2 Litre) had undergone extensive dyno running and was available to be used in the Darrian T90 prototype.

With Geoff Kittney driving, aided by Alan McCann they successfully competed and won the Ears Motoring News Tarmacadam series.

The Millington alloy unit was later homologated as a low volume production engine for Darrian cars.

In 1992 the late John Reid of Holbay Racing approached Roy with a view to supplying a batch of 30 blocks to be used for an open wheeled Formula Classic race series. This enabled Millington's to upgrade from a Moog Hydropath 3000 to a state-of-the-art four axis CNC.

As the years went on development and evolution of the Diamond Series progressed, producing many different N/A and turbo variants. By 1996 Millington's had produced 60 units.

With the capacity taken up to 2.5 litres, Team Darrian Cars and Swansea Institute entered 2 cars in the Privilege Insurance Championship GT3 class, Ken Thomson took overall Championship honours that year.

By 1999 Millington Diamond Engines were used by many, whether it be Pilbeam Racing, Holbay Racing, and Darrian Sports Cars.

Customers were fitting them in Westfield's, Ford Escorts in post historic classics, Turbo Ford Puma 4x4's, several Autograss classes, Hillclimb cars and historic Chevrons in the USA. The Diamond had proved incredibly versatile.

In 2001, with engine numbers up to 260 units, a racing version of the intake restricted turbo rally engine was produced for long distance use. Roy used the blocks internal pillars with a through bolt system that held the head, block and crankcase together as one rigid structure, this unit produced a reliable 493 bhp and 424 ft-lb of torque and only weighing 89kg. Millington's supplied this 2.0 litre turbo variant for Marshall Cook Racing to campaign the ultra competitive American Le Mans series.

The Diamond Series II

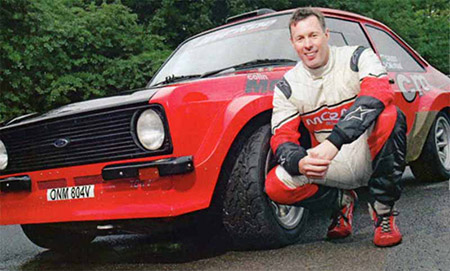

By 2005 the ever evolving Diamond had a name as the ultimate Escort mk2 engine and had now been fitted into Colin McRae's 'out of hours' Escort built by DJM motorsport as the ultimate mk2, but Roy was not content for development to stagnate.

So Millington's decided to design and manufacture their own bespoke cylinder head, based not unnaturally on the YB proven components but with advanced features they wanted to incorporate. Principal amongst these were the included valve angle, millington headwhich at 45° on the YB was thought to be too wide for efficient combustion; the exhaust port shape (designed for a turbo charged road car application so 'pointing the wrong way');reduced weight but retaining plenty of material around the combustion chamber, and incorporating good cooling for turbo charged applications.

After deciding on the different valve angle, a built in Roller barrel throttle and a refined combustion chamber shape, after working closely with Foley patterns Millington's produced the complex set of patterns. Grainger and Worrell's state of the art facility were chosen for the first batch of castings. Once the first set of castings were machined the series II project was well underway, developing into what has now been widely described as possibly the best four cylinder 16 valve engine in the world.

With Roy's long association with Phil Collin's, he was the natural choice for the first Diamond Series II prototype, running untouched for 2000 stage miles. Roy repeatedly suggested that Phil should bring the unit back for him to evaluate but Phil refused, stating that it was running fine and that he wanted to continue using it!

In July 2007 the Colin McRae R4 made its debut at the Goodwood Festival of speed with the 2.5 Diamond Series II being Colin's second Millington engine.

A batch of 20 engines were produced and marked up as McRae R4 units. Unfortunately only two units were ever used for development in the R4 prototype due to the tragic loss of Colin.

The marked up bespoke units were eventually sold off and mainly used in Escorts.

In 2012 Roy and Sheila Millington's son, Julian took over the reigns of the business in a directors position.

In 2017 the workshop received its 3rd extension since it first erected over 35 years ago.

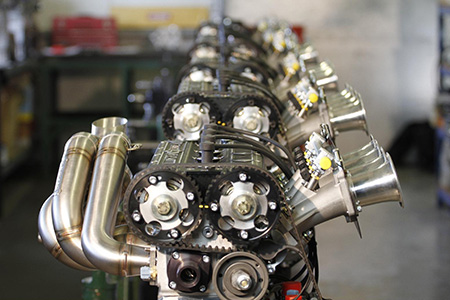

The Diamond is in a constant process of evolution and development whether it be piston shape and material, combustion chamber shape, crankshaft designs, or camshaft profiles.

Millington's are regularly putting the diamond series engine under extensive tests and updates to ensure complete customer satisfaction, whilst going to great lengths to make sure older spec series II's will not become obsolete. This is so that any future updates can be incorporated into existing Series II units.

Currently Millington's feel that the series II has far from reached its full potential as a high performance engine.